Vulcan Robots

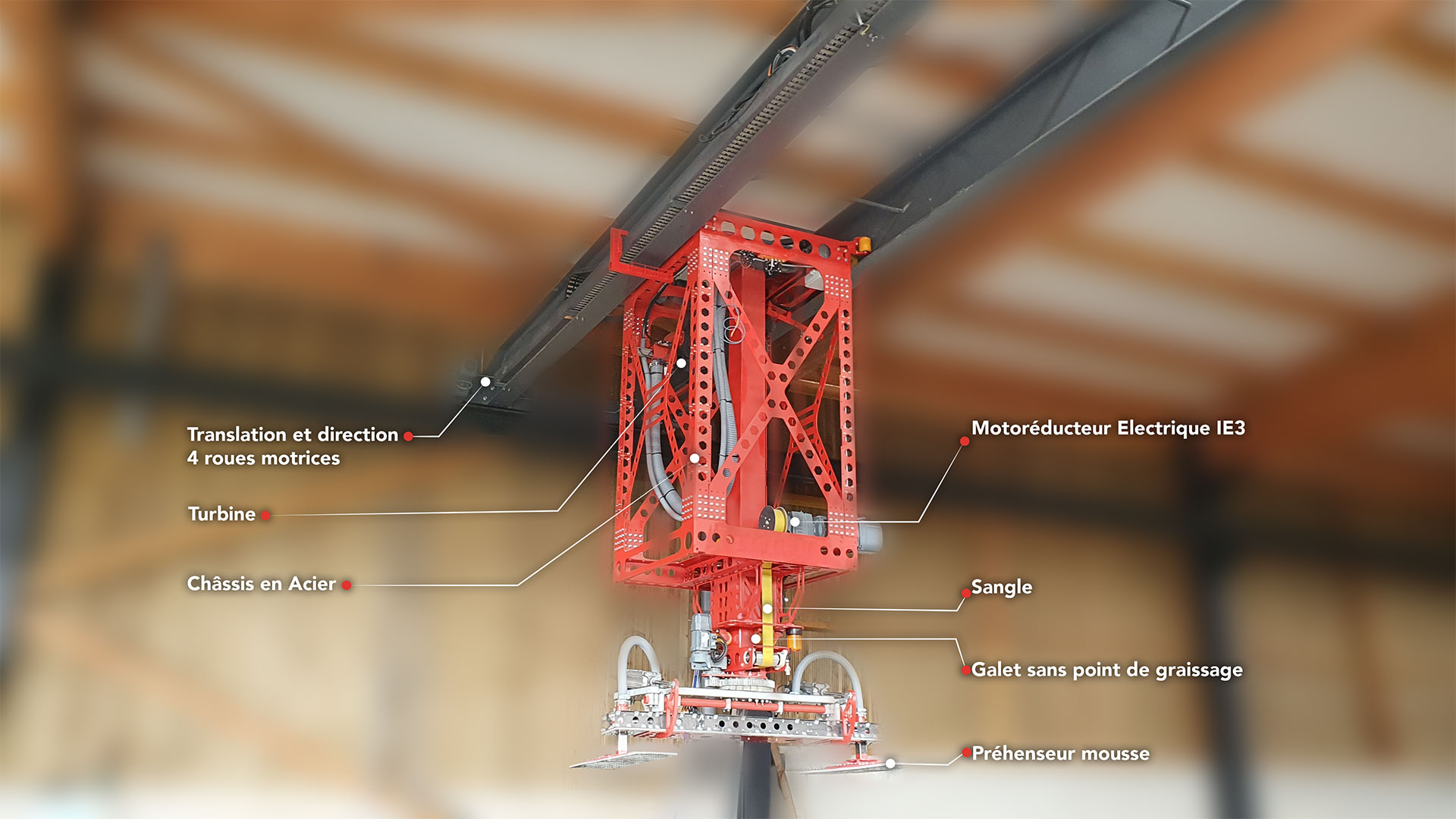

The motors are to IE3 technology standard

Reducing electrical consumption.

Multi-cell gripper for handling rough, porous, deformed products

Monitoring system makes it possible to anticipate the replacement date for the foams

Reducing maintenance costs with optimum suction power

Replaceable foams with two-component adhesive allowing rapid maintenance / replacement.

Lifting by strap, simple and quick, easy maintenance

Smooth movements.

Turbine regulated and controlled by a PID.

Reduced electrical consumption

Noise reduction.

Mousse Process pays particular attention to optimum structure design to reduce moving masses.

The Design Office analyse the structures using RDM software to guarantee sufficient rigidity without penalising electricity consumption.

Rotation

Infinite 360° rotation is achieved using electro-pneumatic rotating joint technology. A crane turret type ring gear allows the rotation of heavy loads with great reliability and precision. An encoder on the motor allows the rotating axis to be positioned automatically.

Laser

Robots enable automatic stacking or destacking over large areas. The manoeuvering area can range from 2m to more than 100m in the transfer direction.

Precise positioning is achieved using laser positioners. Laser technology is reliable and economical, it also requires minimum maintenance.

Polyurethane wheels

Travelling on polyurethane rollers. Reducing noise and wear.

Quiet and maintenance-free. No wearing of the track. All couplings arefitted with clamping hubs making maintenance simple and economical.

Touch screen settings

The robot can be controlled by means of a touch screen allowing total configuration of the robot: speeds, accelerations, positions, viewing the records of production and maintenance information. Connecting by Wifi allows complete remote system support, and visualization of the robot cycle and the stacking zone is also possible.

Radio control

Optional: control by ergonomic radio control equipped with 2 proportional and self-regulating joysticks.

The speed and acceleration are adapted automatically according to the transported load and the position of the robot.

The proportional technology allows fast and very precise movements. The operator can adjust the speed with very high accuracy.

Eco label

The Robots of the Vulcan range are optimalized to gain the electricity saving LABEL. The reduction in weight and installed electrical power reduces movement inertia and therefore energy consumption as well as mechanical wear.

Mousse Process has invented and developed a turbine speed self-regulation system using PID control. This system reduces the energy consumption of the turbine.

Mousse Process invented and developed in 2017 grippers using carbon fibre technology resulting in a threefold reduction in the gripper weights. Almost all Mousse Process-Systems Robots use carbon fibre technology grippers.

Cables M12 standard

Sensors and actuators are connected by M12 standard wiring.

Maintenance is simple, fast and economical. Communication by IO-LINK protocol allows remote observation and fault diagnosis using (WIFI).

Polyurethane rollers

The lifting steel column is guided between 8 polyurethane rollers allowing simple and economical maintenance.

Rotating Beacon

For Maximum Operator Safety.

The rotating beacon improves visibility and reduces the risk of collisions.

Vacuum level monitoring

Vacuum level monitoring, automatic vacuum level regulation and fall protection. Increased foam life thanks to the Predictive VLF system invented and developed by Mousse Process-Systems in 2019.

Speed Regulation

All motors are controlled by frequency converters. Speeds and accelerations can be adjusted by the operator. Acceleration regulation optimizes robot speeds, reduces electric consumption and mechanical wear.

Layer/Single Option

The Vacuum stackers can be equipped with the ‘Layer/Unit’ option, especially designed for stacking timber layer by layer or as single pieces.

A 90 degree rotation allows the grippers to be switched from the ‘layer’ position (orthogonal to the stack) to the ‘unitary’ position (parallel to the stack). Switching is effected using pneumatic cylinders activated by simply pressing a button on the radio control.

Tilting option

Pivoting makes it possible to turn a beam or a panel from the horizontal to a vertical position. It is useful for feeding vertical panel saws, or for turning large section beams.